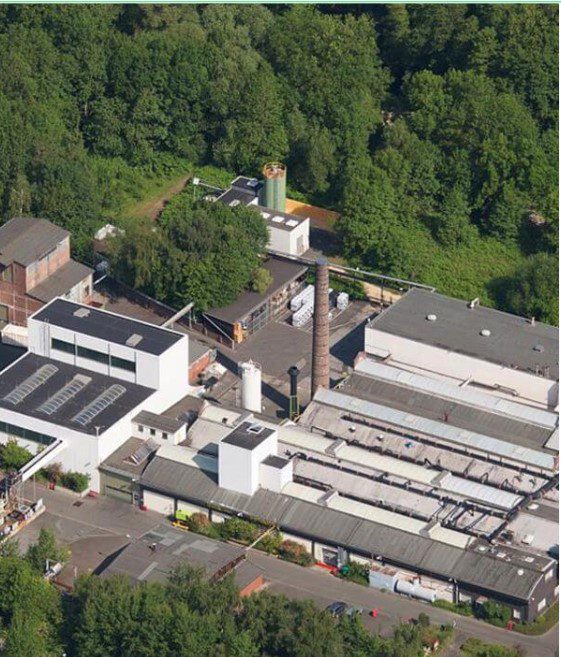

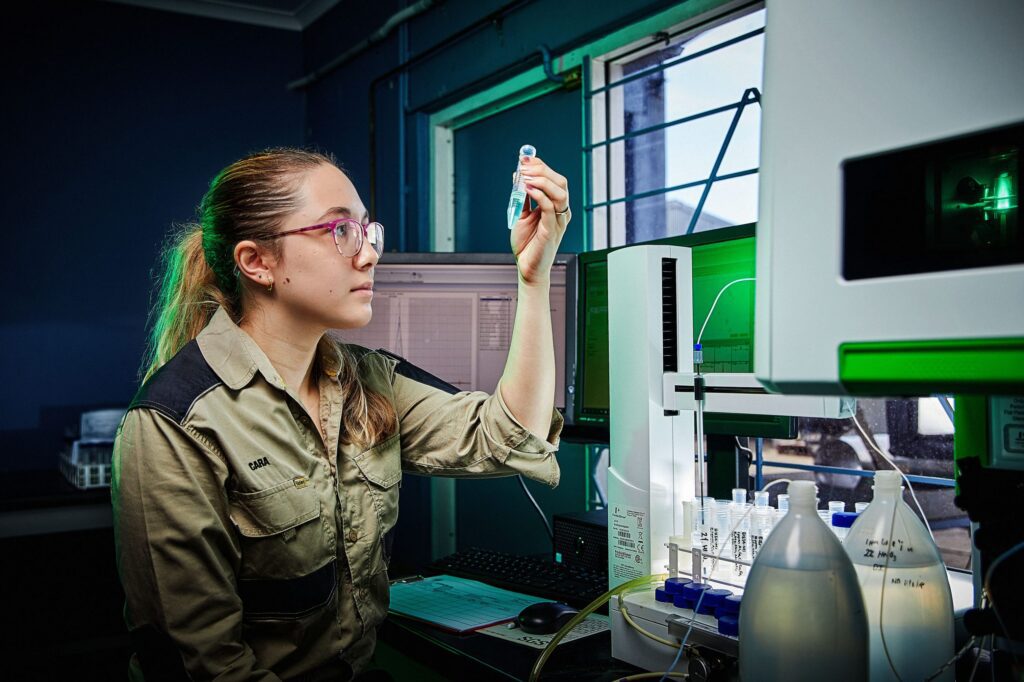

Pure Battery Technologies (PBT), headquartered in Brisbane, Australia, with a German subsidiary in Ettlingen, produces the precursor for nickel-based active cathode material (pCAM), which is used in lithium-ion batteries required for electric vehicles (EVs). PBT’s environmentally friendly, cost-effective processes for the production of active precursor cathode material (pCAM) were developed together with the University of Queensland. We produce high-quality battery materials with a much lower environmental impact and are much more cost-effective than the processes currently in use.

PBT Corporate Video