Decarbonising industry

Catalyco

Commercialised by

Catalyco

Riga, Latvia

Uriekstes street 3/k-1, LV-1005 Riga, Latvia

A circular economy supply chain for ZnO to help industry meet ESG targets

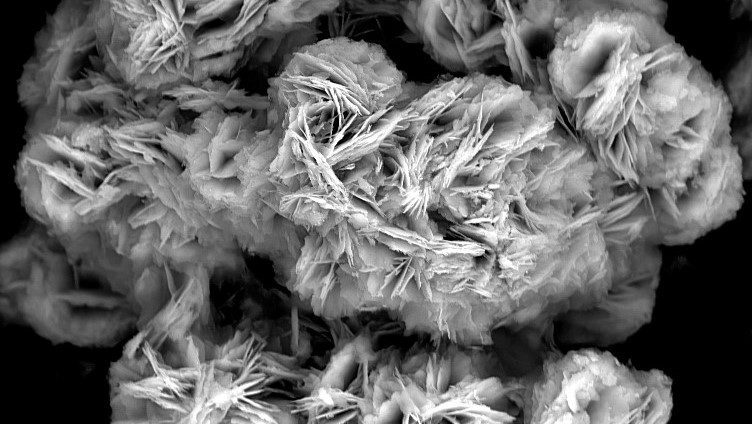

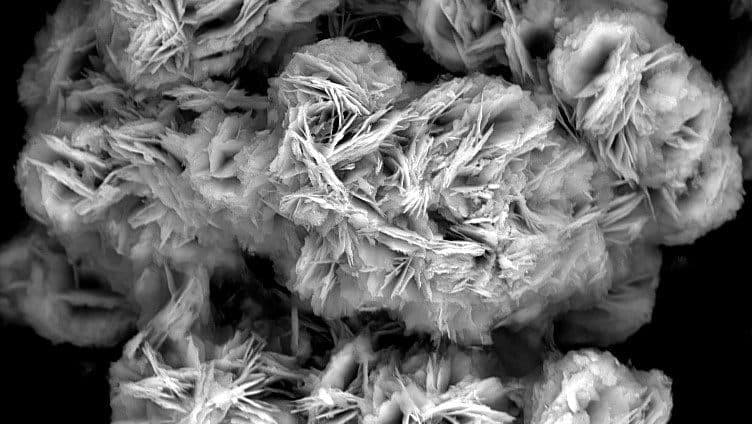

Catalyco focuses on creating a sustainable and local supply chain for zinc oxide (ZnO), by extracting it from industrial waste streams. The company manufactures advanced ZnO products that have unique characteristics and provide added value in an environmentally friendly way. The potential applications of these products include the tyre and rubber industry, as well as adsorbents and catalysts. Additionally, the high purity of the ZnO makes it suitable for use in the cosmetics sector.

The need

Zinc oxide (ZnO) is vital for tires, rubber, ceramics and chemicals, with no scalable substitute and rising demand. Europe imports 40% mainly from China and the US, impacting stability. Local waste streams hold large ZnO reserves, but cause pollution if unused.

The solution

Catalyco recovers high-purity ZnO from chemical and metallurgical waste, creating a closed-loop system that supports the circular economy. Our process secures an alternative ZnO supply for Europe, reduces greenhouse gas emissions, saves energy, cuts raw material use and diverts industrial waste from landfills – helping to meet EU climate goals.

The value proposition

- The process developed to extract ZnO from industrial waste streams helps to establish a local supply chain.

- The chemical industry gains from the promotion of a circular economy and in enabling the reuse of materials, reduces costs and ensures a more secure supply of materials.

- The rubber industry benefits from reduced consumption and costs by utilising recovered materials, improving rubber characteristics, and complying with legislation.