Renewable energies

FiberSail Holding

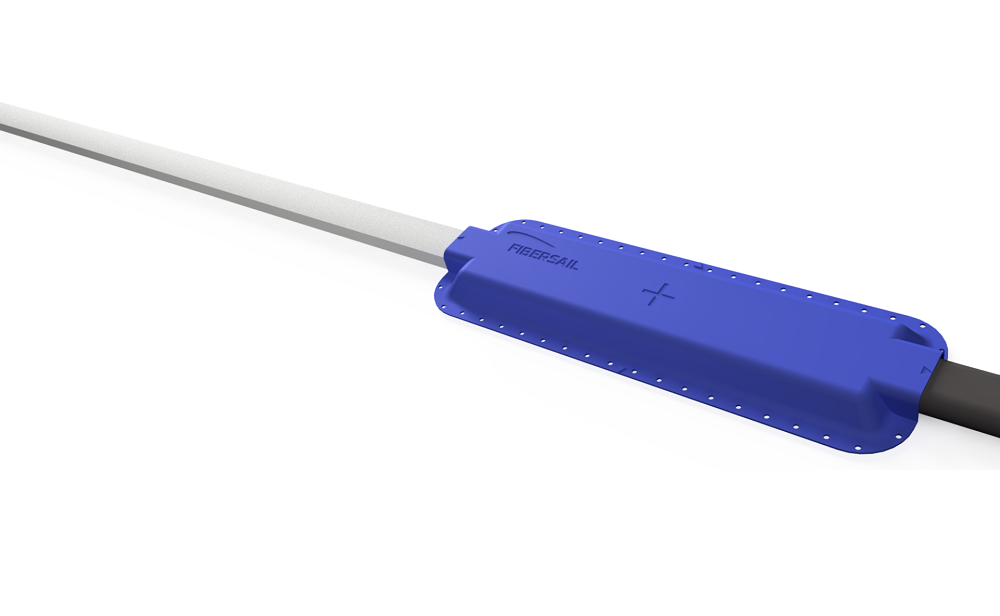

A shape-sensing system based on fibre optic technology able to measure the deformation of blades during operations.

Commercialised by

FiberSail Holding

Amsterdam

Stationsplein 45, 3013 AK Rotterdam, Benelux, Netherlands

Creating Value with Smart Blades

FiberSail’s shape-sensing system, based on fibre optic technology, delivers real-time wind turbine blade monitoring and controlling by measuring blade deformation during operation. With a simple installation process and full-blade visibility, it enables turbines to prevent excessive loads, reducing failures and unplanned downtime. By detecting unidentified loads—a key cause of underperformance and rising maintenance costs—FiberSail helps reduce O&M costs by up to 10% and increase Annual Energy Production (AEP) by up to 3%, ultimately saving wind projects’ financial viability. With over 55 MW under monitoring and 76,000 operational hours, this ready-to-scale solution strengthens asset reliability across the wind sector.

The need

Large wind turbine blades show increasing failure rates. Undetected damages can quickly propagate and lead to soaring repair costs, lengthy turbine downtimes and even blade failures. Some owners report several million euros worth of losses each year due to lower productivity and high repair costs.

The solution

Fibersail offers a unique blade condition monitoring system that detects damages at an early stage and provides alerts to owner/operators of wind farms. Our highly-sensitive shape sensor mounted inside the blade monitors blade deflection and natural frequency variation. When damage occurs an instant alert is transmitted through our dashboard. Owners / operators can then act swiftly, preventing blade failure and radically reducing repair costs.

The value proposition

- Highly-sensitive detection of early damage inside the blade.

- Accurate assessment of remaining lifetime.

- Increased AEP through shorter repair duration, and additional pitch and yaw optimisation.