Energy storage

GDI

GDI’s patented silicon battery materials offer better performance over standard lithium-ion and emerging solid-state batteries. GDI batteries use the power of Silicon to achieve faster charging times, greater energy density and superior safety.

Commercialised by

GDI

Eindhoven, Noord-Brabant, Netherlands

Luchthavenweg 10, 5657 EB Eindhoven, Noord-Brabant, Netherlands

100% silicon anodes that enable longer-lasting, faster-charging batteries with a secure supply chain

Visit siteThe need

Electrification is creating a growing demand for batteries. However, they must not only offer higher energy density, faster charging and an excellent safety profile, but have a secure supply chain and be manufactured with a low-carbon footprint.

The solution

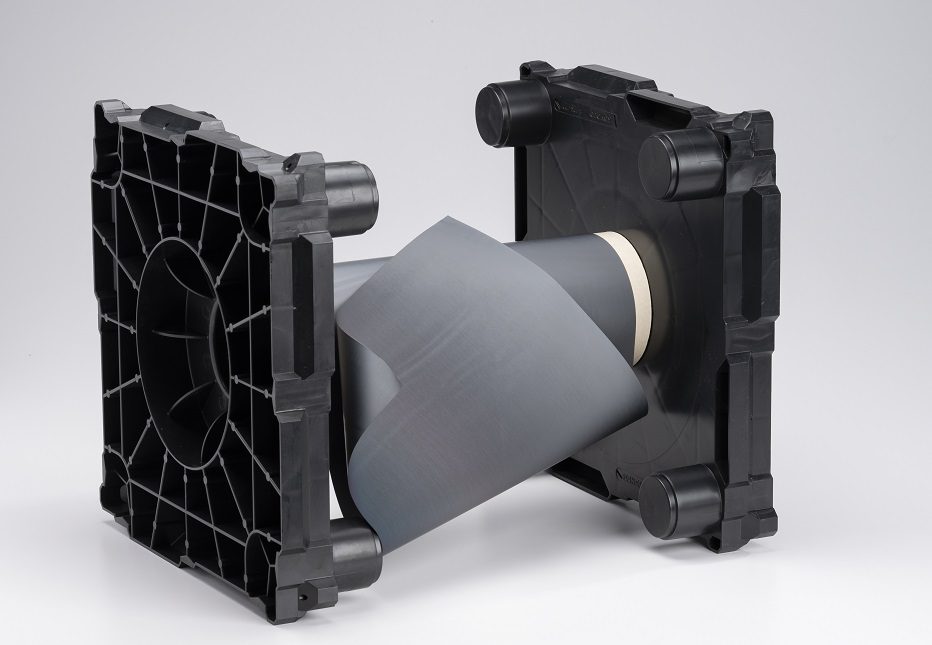

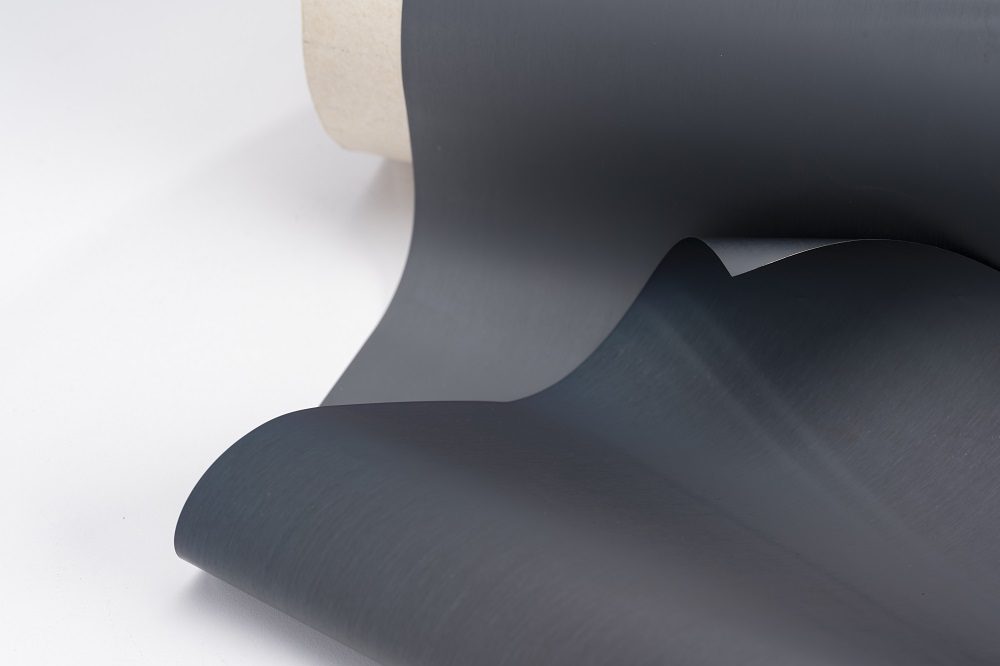

GDI’s 100% silicon anodes replace traditional graphite anodes in lithium-ion batteries, affording 30% higher energy density and 3x faster charging without sacrificing safety. The supply chain of copper foil and silane gas precursor is entirely EU/US-based, with manufacturing taking place in the Netherlands and Germany. Automated roll-to-roll production is highly efficient, leveraging industrial equipment and facilities that already operate at scale.

The value proposition

- GDI supplies customers with rolls of finished anode and works with them to optimise battery cell architectures to meet differing needs.

- Higher-performing batteries for use across many industries.

- A fully EU/US supply chain and manufacturing operation mitigates global geopolitical and supply chain risk.

- Designed for safety, batteries with GDI anodes have passed extensive nail penetration safety testing.

- Unlike traditional graphite anodes, the production of GDI anodes is entirely carbon free.