Decarbonising industry

Accelerating the decarbonisation of hard-to-abate industry

Commercialised by

Stegra

Stockholm, Sweden

Riddargatan 23 A, 1 tr., 114 57 Stockholm, Sweden

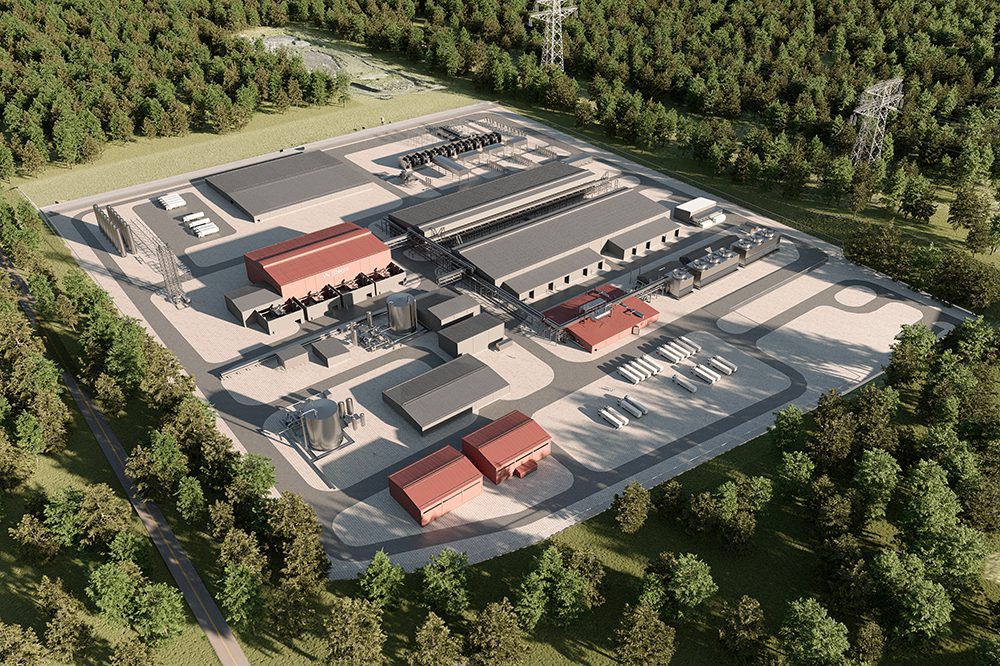

Stegra is an industrial impact scale-up in the process of building its first plant for large-scale production of green hydrogen, green iron and green steel. Founded in 2020 as H2 Green Steel, the company rebranded to Stegra in 2024 to better align with its mission to decarbonize hard-to-abate industries. Beginning with steel, Stegra is constructing a flagship near-zero-emissions steel production facility in Boden, Northern Sweden. The project has secured permitting and financing totaling approx. €6.5 billion, with production set to commence in 2026.

The need

Cleaning up heavy industry, which is responsible for 40% of all global CO₂ emissions, is key for tackling the climate crisis. The steel industry alone accounts for more than 7% of the world’s CO₂ emissions.

The solution

Stegra, previously H2 Green Steel, builds a fully integrated, digitalized, and circular plant in Boden, northern Sweden. Their giga-scale electrolyzer, powered by renewable electricity, will be the largest green hydrogen production plant in Europe. By swapping coal for green hydrogen, Stegra refines iron ore into green iron, emitting steam – just plain water. This is game-changing innovation making it possible to produce near-zero emission steel, setting a new industry standard.

The value proposition

Related news